We will serve you to the best of our capacity with the help of our expert team

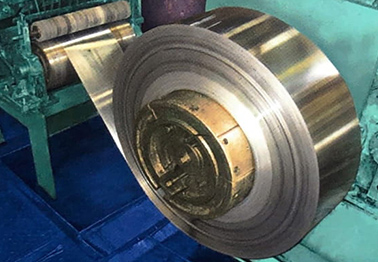

The basic raw material required for production of Cold rolled material is Hot Rolled coil. Selection of Raw material is done based on the customized needs of the customer . Our Raw materials are sourced from reputed raw material manufacturers viz like JSW, ESSAR , Tata from indigenous markets and imported material from Nippon (Japan), Posco (Korea) etc. based on the chemical, Mechanical, Metallurgical & Physical properties required by the customer.

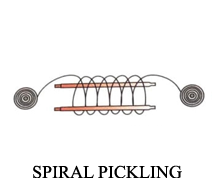

In order to produce smooth surface finish of the cold rolled steel strips, the hot rolled coil has to be cleaned by means of Hydrochloric acid. This process is called Pickling

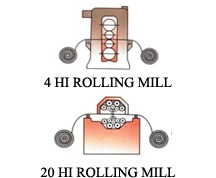

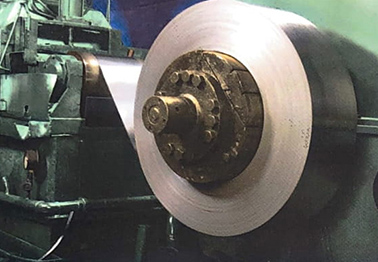

Thickness of pickled coils is reduced by rolling in 4-Hi/20-Hi Mill to the desired thickness. This is achieved in Rolling Mills.

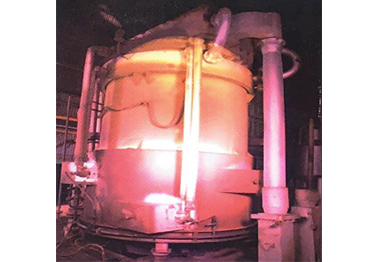

This involves, softening of the hard rolled coils by heating in a furnace whose temperature and atmosphere is controlled. This improves the mechanical properties and the desired metallurgical properties are achieved.

Here the annelead coil is given a reduction of 0.50% to 2.00% to achieve The desired thickness and physical properties as specified by the customer. In addition the pronounced yield point is obviated and surface finish is improved. Surface finish whether bright or matt, is achieved by using suitable rolls.

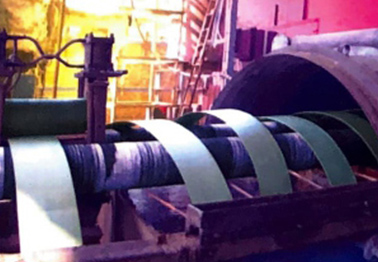

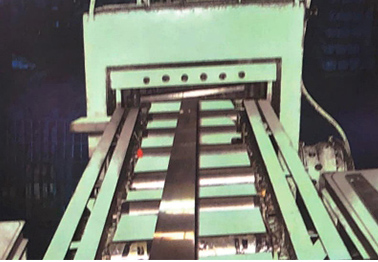

To achieve the final finish size in width the coils are slitted in rotary Shear.

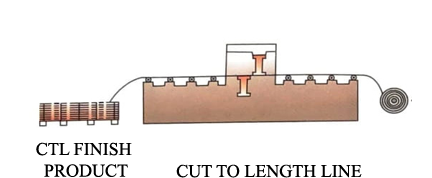

The coils are flattened and cut to specified length

The finished strips are adequately oiled with rust preventives and wrapped in polythene, HOPE or alkathene hessian cloth & palletised as per requirement. Special packing is also done as per requirement of customer.